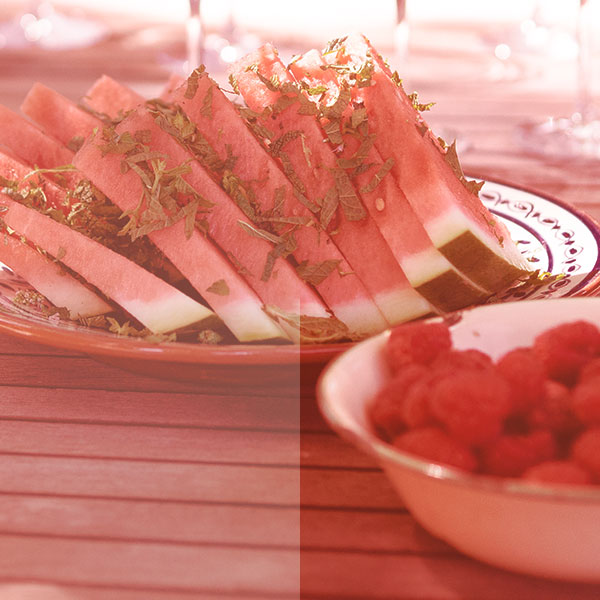

Brut Rosé

The refreshing cuvée

from the exquisite grape varieties of Valais

Drawing on over 30 years of experience in sparkling wine, this cru first entered our cellars in 2012. The effervescent rosé with a fruity flavour completes the sparkling Jacques Germanier range. The sophisticated cru is aged in 800 m2 of tunnels carved out into the rock which guarantees a consistent temperature throughout the year. The Brut Rosé has been developed in the same way as our Champagne neighbours from the start, benefitting from age-old knowledge. This effervescent 100% AOC Valais with summer fragrances and exceptional flavours is the result of a unique location, centuries of expertise and quality Valais grapes.

IMPOSSIBLE TO IMAGINE SUMMER WITHOUT THE BRUT ROSÉ FROM NOW ON!

Enjoy the intense freshness of our fruity bubbles that will make your summer evenings a success. Order your bottle now!

TRADITIONAL METHOD

PRESSING

To develop our sparkling wines, the grapes are pressed whole straight after the harvest. The quality of the grape must varies depending on the pressing and only 50% of the must is retained for the Brut.

FIRST FERMENTATION

The grape must undergoes a first stage of fermentation, known as the alcoholic fermentation. Yeast is added which transforms the sugar in the grape must into alcohol. It allows the flavours of the wine to develop.

DRAWING OFF

A drawing liqueur is added to the cuvée before it is bottled. The wine is drawn from the tanks and bottled with a stopper. The bottles are then placed on wooden slats inside our tunnels to ensure a consistent temperature (10°) all year round. They are stored here for 24 months.

SECONDARY FERMENTATION AND RIDDLING

Stored in glass bottles and thanks to the actions of the yeast, the sugar is transformed into alcohol and carbon dioxide which creates the foam and bubbles: this is known as the secondary fermentation. Once all the sugar has been transformed into alcohol, the yeast is deposited on the walls of the bottle and forms a solid deposit.The riddling process aims to concentrate the deposits in the neck of the bottle. To achieve this, the bottle is placed upside down on a rack and shaken.

The riddling process is a stage which is a real feat! What is required is to gradually cause the deposits to slide down without leaving the finest particles suspended in the bottle. The bottle is turned in one direction or the other, with the rotation varying between a ¼ or 1/16th of a turn each time. At the same time, the gradient of the bottle is progressively increased. Riddling is a precision operation and the sequence of rotations and manner in which they are carried out leaves no room for guesswork.

DISGORGEMENT

Once the dregs have collected in the neck, they need to be removed from the bottle. The neck of the bottle is submersed in an icy solution. This triggers the formation of an ice cube containing the solid deposit. This ice cube is then ejected under pressure when the bottle is opened. The addition of the expedition liqueur is then the final stage in this traditional wine-making method.